Cylinder Cyclone Features

An all-in-one machine for disassembling, reassembling, and pressure-testing cylinders.

see callouts for more information

Center Pipe Construction

• Carries out all operations in one

stable, simple unit.

• All pressure and torque forces

contained within the machine.

• Three oil reservoirs provided: waste oil (250

gallon capacity), main machine system (25

gallon), and pressure test system (55 gallon).

Sky Hook

• Overhead crane rail with rolling chain hoist with a 3-ton capacity.

• Center-lined for perfect assembly and disassembly.

• Integral part of the Cylinder Cyclone making alignment a simple task.

• Fitted with a overload stop switch to maintain safe operation.

AccuraTorque Head

• Model CC-2050-CPB provides up to 50,000 ft⋅lb for loosening or 37,550 ft⋅lb for tightening cylinder nuts and Model CC-2060-CPB provides 60,000 ft-lb loosening and 50,000 ft-lb tightening.

• Infinite pressure control between 0 - 50,000 ft-lbs of torque.

• Bi-directional head rotation.

• Remote controlled rotation.

• Designed to accept specialized tooling to quickly change from one operation to another.

• Reassemble cylinders to manufacturers specifications with complete confidence.

Ball Screw

• 2 Ball screws with support system.

• Creates the pushing and pulling action of the torque head.

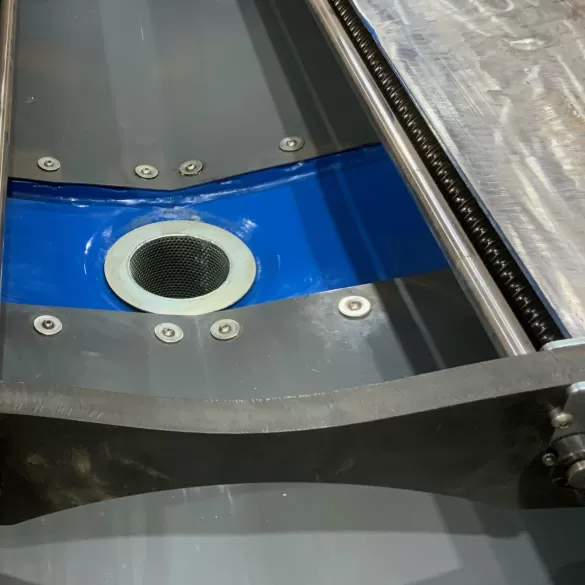

Drain Screen

• Drain Pans slope toward the center of the unit, funneling waste oil into the large reservoir.

• Removable screen prevents tools and hardware from disappearing.

Hydraulic Pumps

• Two completely separate systems-

main system and pressure test system.

• Equipped with low oil lights and alarm

system.

Filter System

• Two completely separate systems-

main system and pressure test system.

• Equipped with low oil lights and alarm

system.

Electronic Control

• Wireless remote enables safe machine operation from a distance.

• Touchscreen control panel provides precise machine control and monitoring.

– Torque pressure shown in ft./lbs.

– Pressure testing performance

shown on graphs.

– Printing option available to print

out pressure test results.

Digital Display

• Digital touchscreen display.

• Gives values in a format that’s easy to understand and is of value. Supports different units and languages.

• Provides reporting capabilities that can be printed out with the optional report printing kit.

• Provides diagnostics for the bench.

Large Tooling Section

• Specifically engineered for the

Cylinder Cyclone bench.

• Tooling can be purchased individually

or in one of 4 different packages at

significant discounts.

• Custom tooling available upon request.

Cylinder Cyclone Features

The more you observe the Cylinder Cyclone in use the more you will realize this machine was built by shop mechanics, not by someone who has never had in-shop experience. This hydraulic cylinder servicer or hydraulic cylinder bench makes a simpler and cleaner operation out of one that might be downright dangerous and dirty by using ordinary tools. Wouldn’t you like to service your cylinder in an environment that was planned and built by people who know what is involved in the processes?

Center Pipe Construction

This center pipe provides the rigidity and strength to handle high torque operations. It also makes placing the machine a simple task. While you will need a solid base to set the machine on, the pipe will hold the machine rigid and adjusting the placement is a very simple operation. Many of the competitors offering require pouring expensive piers and bolting the machine to the floor.

The entire challenge of managing the oil that makes hydraulic cylinders operate is solved by the waste oil receptacle that is directly under the cylinder that is being taken apart. When a cylinder is dissembled, the power of the Cylinder Cylone controls where and when that oil is dispensed into proper holding tank until you are ready for it to be sent for recycling or disposal.

The same pipe that has a tank for waste oil, also has a reservoir of fresh oil to refill the cylinder and test it for insurance against leaks. Likewise, the system oil for the hydraulics of the machine is all contained in a separate tank within the pipe.

Sky Hook

The Sky Hook is an overhead rail that provides crane service for your handling heavy cylinders while in the bench. It has a rolling chain hoist that can handle cylinders up to 3 tons in weight, and at the same time give precise movement that make a one-man set-up a breeze. This Sky Hook is perfectly aligned over the center points of the AccuraTorque Head and the tail stock, so the cylinders are held exactly where you need them to be for effortless servicing and testing.

This feature greatly enhances the safety of the Cylinder Cyclone. We expect this machine to give you many hours of secure service after you have acquainted yourself with the simple procedures of operation.

Hydraulic Pumps

We know hydraulics and have installed top of the line pumps that should serve your needs reliably for many years. There are two separate pumps because for servicing the two separate needs. The one need is to operate the hydraulics of the Cylinder Cyclone Repair bench. The second is to test the repaired cylinders before they are sent back with the customer. This way your hydraulic cylinder repair shop can ensure reliable service or your rebuilt cylinders.

Electronic Controls

Accurate controls on a machine are an essential component for both safety and for accuracy and precision. We use wireless electronic controls that enable the operator to make the Cylinder Cyclone perform from a safe distance. We also use a touchscreen so the operator can monitor and control what is happening to the cylinder at all times. We offer a printout option so the client can be given the exact details on what tests have been performed on his cylinder.

Pressure Test System

This feature enables the technician to properly test rebuilt cylinders before they are removed from their repair setup. Also, all of the oil that was used to test the cylinder may be purged and recycled in the process to better preserve our environment.

Specialized tooling

Since we know our machine, and we know the cylinder rebuilding industry, we were able to put together a complete array of service tooling for the Cylinder Cyclone. These tools are thoughtfully engineered to serve your needs in repairing hydraulic cylinders.